This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Is Your WMS Holding You Back? Discover the Hidden Potential of WES

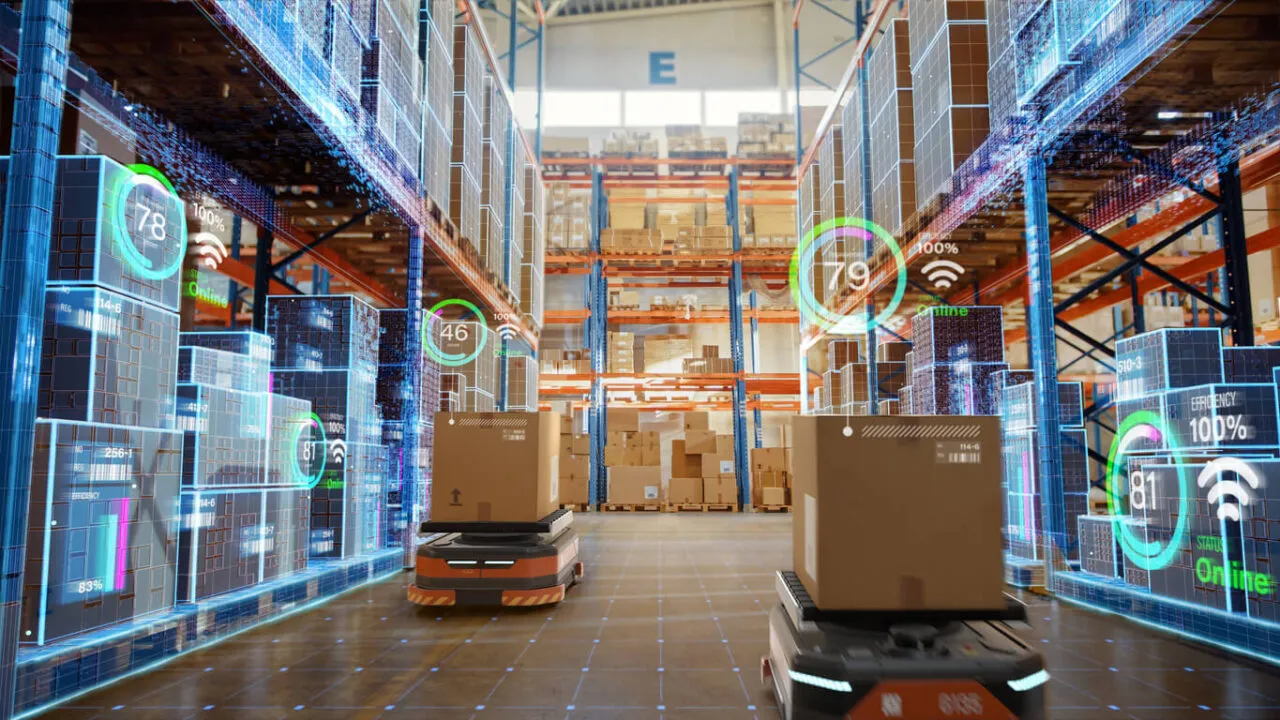

Warehouses today are dealing with unprecedented challenges: soaring order volumes, unpredictable supply chains, and persistent labor shortages. To keep pace, efficient operations are paramount. While warehouse management systems (WMS) have been a cornerstone of many facilities, the extent of that software’s reach can be limited—particularly as operations add more automation. Enter warehouse execution systems (WES). Here’s a quick overview of what these warehousing softwares are, and how warehouse execution systems can supplement a warehouse management system.

Understanding Warehouse Management Systems and Warehouse Execution Systems

When considering warehouse software, organizations may wonder what the differences are between a warehouse management system and a warehouse execution system. In the last decade especially—as software vendors increase the capabilities of each—the lines between the two have increasingly blurred. However, there are some fundamental differences.

Operations have been deploying warehouse management systems for nearly 50 years. As the amount and diversity of inventory that companies handle and distribute has grown, so too has the complexity of tracking and managing it with paper or spreadsheets. Conversely, deploying WMS software offers a more comprehensive way to manage and coordinate inventory. It tracks inventory levels and item movement within the facility by stock keeping unit (SKU), quantity, location, and transactions.

A WMS also directs the processes surrounding the handling of inventory, end-to-end. Using a WMS streamlines and automatically plans and controls complex workflows to handle items, from the point of receipt at the dock to put away, picking, order consolidation, and ultimately to shipping. This improves inventory accuracy while speeding up order fulfillment and delivery times.

When automated equipment started being introduced into distribution centers (DCs) and warehouses, software known as warehouse control systems (WCS) was developed. A WCS translates information and instructions from the WMS into functional commands that direct the actions of the automation, such as conveyors, sorters, scanners, and more.

As operations increasingly implement more automated solutions, it’s becoming more challenging to synthesize and integrate all of them into a unified system. That’s especially true when the technologies’ original equipment manufacturers (OEMs) are different. Enter warehouse execution system (WES) software, which combines a WCS with some of the functions typically handled by a WMS.

A warehouse execution system manages order planning, assigns and releases tasks intelligently, orchestrating all current work, and reprioritizes it continuously to optimize process flow. Typically deployed in facilities that utilize both manual and automated processes, as well as in completely automated operations, a WES helps with high-throughput order fulfillment. It has visibility into all workflows, synchronizes automated and semi-automated equipment with manual tasks, and dynamically reallocates labor and work to ensure all order delivery deadlines are met.

How Warehouse Execution Extends Warehouse Management System Capabilities

There are a variety of reasons why an operation may elect to add a WES, either to supplement an existing WMS, or instead of implementing one. Sometimes, the original software vendor no longer supports a facility’s current WMS, and upgrades are not feasible. A WES could extend the capabilities of their existing inventory management solution without requiring a full replacement of the current system.

Similarly, many companies have a “home grown” warehouse management system programmed solely for their use. Yet, as their order complexity has grown, enhancing the capabilities of a custom WMS is often difficult or cost prohibitive—as the original programmers are usually no longer available. Deploying a WES can enable support for new functionalities, technologies, and processes without modifying the warehouse management software.

Even DCs with an up-to-date WMS from a major software supplier may discover that their need for overarching synchronization of disparate automated systems requires a higher level of operational control. Because it combines inventory management functions with end-to-end equipment and process orchestration, a WES may be the optimal choice to achieve the desired level of visibility and workflow adaptability.

A Warehouse Execution System Solution: DATUM

Implementing a warehouse execution system, such as DATUM, allows an operation to increase its agility, flexibility, and reliability by expanding current capabilities beyond the limitations of an existing warehouse management system. Because Designed Conveyor Systems designed and engineered DATUM from the ground up, the WES easily interfaces with a range of WMS software—whether from major suppliers to homegrown.

Its flexible, secure API gateway and integration bridge also allow DATUM to connect to and leverage a range of new and existing semi-automated and fully-automated equipment. In many cases, it can take over the control and function of older technologies, extending their usable life. These include:

- Conveyor systems

- Sortation systems

- Autonomous mobile robot (AMR) fleets

- Goods-to-person fulfillment automation

- Light-directed picking

- Automated storage and retrieval systems (ASRS)

- Unit sorters

- Auto-baggers

- Conventional and robotic palletizers

- Voice-directed picking

- Pick and put walls

- Mobile devices

- Automated print-and-apply systems

- Custom cartonization equipment

Additionally, DATUM enhances visibility throughout an entire operation, providing real-time, comprehensive reports on key performance indicators (KPIs) through dashboards. Built-in analysis of order status, labor productivity, and handling equipment alerts managers to issues before they become significant problems, minimizing downtime and facilitating exception handling. With limited connectivity, analytics, and reporting, most WMS software cannot offer comparable insights.

Is a WES Right for You?

In conclusion, the fast-paced demands of today’s distribution centers and warehouses often exceed the traditional capabilities of a WMS. Operations that leverage a WES to complement a WMS, however, can significantly enhance order fulfillment, inventory management, and labor productivity to unlock a new level of operational efficiency and profitability. Contact our team at Designed Conveyor Systems to learn more about DATUM, our warehouse execution software.